Installing new tappet blocks is pretty straight forward, but there are still a few things you should be aware of.

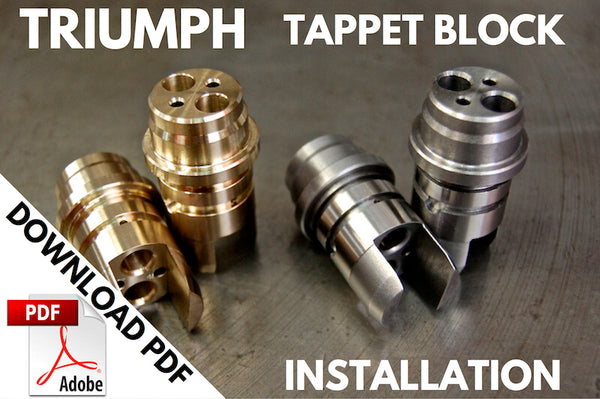

Kibblewhite racing tappet blocks are made of mill certified 674 bronze and cast iron, are machined to accept higher cam lift (up to .450”), and are designed to outlast the original factory tappet blocks and produce more accurate valve timing. A few things must be observed before, during, and after installation to take full advantage of the benefits of these high performance USA made parts.

From the flange down, these are externally the same dimension as the Triumph p/n 70-9353 exhaust block used from 1969 to 1982. There is a provision for a tappet oil feed as on the original 69-82 exhaust tappet block, However when also used for the intake side there are no problems. Use the correct O Ring on both top grooves, Triumph p/n 70-7563 or 70-8782. We also suggest a thin bead of Hylomar AF or Hylomar M on the tappet block above the O Ring to insure a leak free seal. Use the correct tool (p/n 61-6008) to install in block squarely. Pay attention to the sound if driving it in, when it bottoms out, stop!

Please note that the tappet block bore is at a 3.5 degree angle towards the inside of the cylinder!

Warming the cylinder can make installation easier. Alignment of the tappet block is extremely important for camshaft longevity.

The inner diameter of the tappet block bore is .3110” and should not need additional clearance, but always check to make sure the tappets are a good fit after installation. If additional sizing is needed any method used for sizing valve guides may be employed.It is also recommended that the tappet block retaining screws are sealed with a copper washer, Triumph p/n 70-2441.